Popular words:

Products

Tombstone Gravestone Monument

Granite & Marble Tiles

Granite & Marble Slabs

Countertops & Vanity tops

Stairs & Steps

Window Sills

Column & Pillar

Mushroom Stone

Balustrade,Railing

Kerbstone

Paving,Cobblestone

Pool Coping

Mosaic

Medallion

Wall Panel

Materials

Home>News

- How to Make a Granite Headstone

- Read: 2832 Add Time: 2023-01-05

-

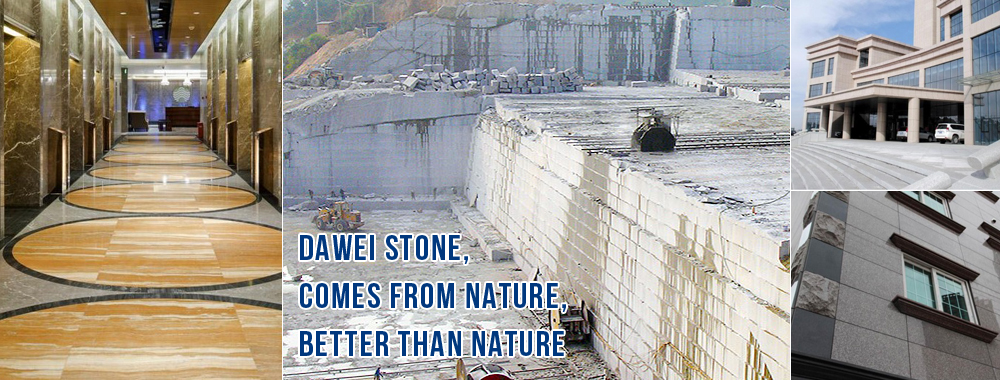

1. The first step is at the quarry. Granite blocks are cut from the bedrock. The most common way of doing this is drilling. A pneumatic drill bores vertical holes in the granite along the cut line approximately 20 feet deep. The quarry men then use steel bits with steel teeth to cut away at the core of the rock.

1. The first step is at the quarry. Granite blocks are cut from the bedrock. The most common way of doing this is drilling. A pneumatic drill bores vertical holes in the granite along the cut line approximately 20 feet deep. The quarry men then use steel bits with steel teeth to cut away at the core of the rock.

2. Granite blocks are usually about 3 ft wide, 3 ft high, and 10 ft long, weighing about 20,250 lbs. After the granite block is cut loose, workers either loop a cable around the block, attach the cable to a large derrick that lifts the granite block onto a flatbed truck that transports it to the headstone manufacturer.

3. After arriving at the granite manufacturer, the granite slabs are then cut into smaller slabs. The slabs are generally 6, 8, 10, or 12 inches thick. This step is done with a rotary diamond saw. The saw is equipped with a 5 ft or 11 ft solid steel diamond blade.

4. Now the cut slabs are polished. The cut slabs are passed under a varying number of rotating heads (usually eight to 13) with differing levels of grit arranged from the most to the least. The first few heads have a harsh diamond grit, the middle heads are for honing, and the last few heads are equipped with felt buffer pads. These pads have water and aluminum or tin oxide powder on them to polish the stone to a smooth, glossy finish. The headstone is then ready for finishing. The granite slabs are either cut or rock pitched into the desired shape and size. Rock pitching is a cutting technique that involves chiseling the outer edges of the stone by hand, giving a more defined, personal shape. Then the monument is crated and sent to the monument builder.

5. The design department will take the customer ideas and create a headstone layout showing in detail what the finished memorial will look like. This will be presented to the customer for approval of the art work and inscription.

6. After the designed layout for the headstone or memorial is approved, the engravers use the computer generated artwork in the form of a stencil to carve the memorial. This stencil is used as a guide to engrave any information, such as words, dates, or emblems, into the granite headstone surface. In earlier years, the design was hand drawn onto the stone, and then hand-carved. Having the customer involved in every part of the design and signing a final proof ensures that the engraving will be exactly as presented. Computer systems have improved the accuracy and precision of monument building, but the process is still greatly reliant on the artisan’s skill and ability to work with the computer programs, machinery and carving processes.

7. Once the stencil has been applied, the granite is then carved by a craftsman. The engraver uses a high-pressure air hose to trace the design from the stencil into the granite headstones. Once the design is carved from the stencil, the engravers fill in the crevasses with black or white little, so that the lettering stands out against the natural coloring of the stone. The uncut portion of the stencil is then removed, and, after the standard final preparations, the granite headstone is ready to be shipped.

You can add photos, vases, and other items to personalize your headstone memorial.